Whoa, this completely flew under my radar…

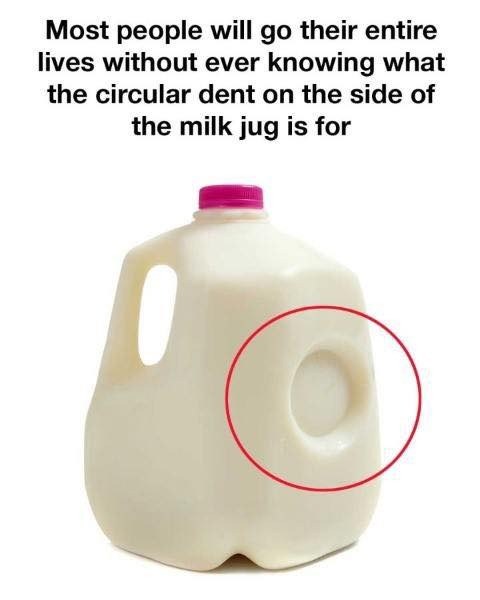

Most people never think twice about the small, round dent on the side of a plastic milk jug. It looks like a random flaw, but in reality, it’s a brilliant piece of design. That little indentation quietly improves safety, durability, sustainability, and even recycling.

The dent works as a built-in “flex zone” that helps the jug handle pressure. Milk jugs are made from lightweight plastic to reduce cost and material use, but this makes them vulnerable to stress. When milk expands or contracts with temperature changes, the dent allows the jug to flex instead of cracking or leaking. It acts much like an expansion joint in a bridge, giving the structure controlled space to shift without breaking.

It’s also a shock absorber. Whether jugs are dropped in a store, bumped in your fridge, or handled during transport, the dent cushions the impact. Like a car’s crumple zone, it prevents the jug from bursting and creating a sticky mess.

On top of safety, the design supports sustainability. Because the dent strengthens the jug, manufacturers can use less plastic overall, lowering costs, conserving resources, and reducing carbon emissions in production and shipping. Once empty, the dent even makes it easier to crush the jug for recycling, saving space and improving efficiency.

What seems like a tiny detail is actually a clever example of everyday engineering. Just as pen-cap holes or jean watch pockets serve hidden purposes, the dent in a milk jug shows how thoughtful design makes life easier without us ever noticing. Next time you pour a glass of milk, you’ll know that little dent is a quiet hero of smart design.

Post Comment